Easy to Maintain

Low Service Costs

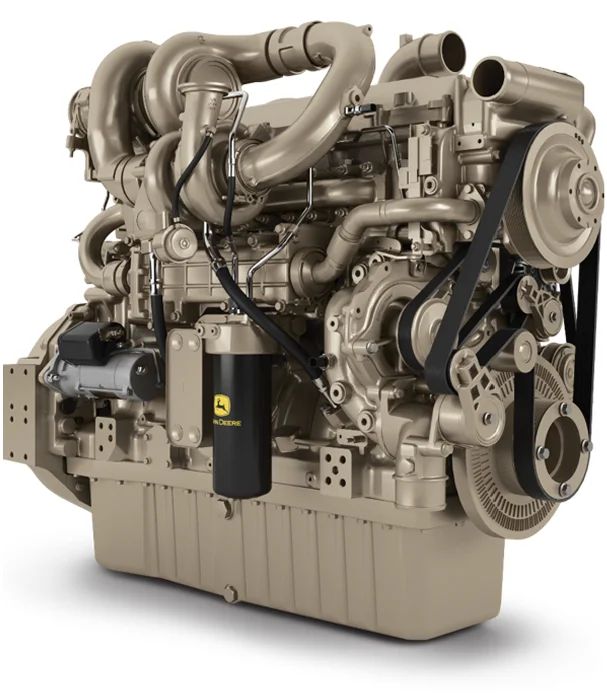

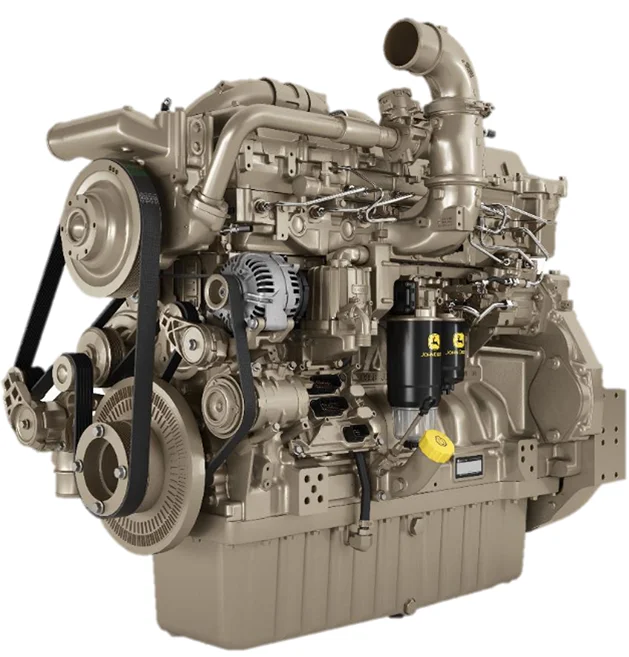

John Deere engineers streamlined common maintenance steps on the JD14 engine.

- Hydraulic lash adjusters decrease valve wear longer engine life while eliminating valve lash maintenance.

- An advanced control system analyzes sensor data to keep operators working without interruption.

- Prognostic capabilities are built into the engine to help users identify potential problems and schedule service prior to downtime.

- Proven John Deere cooling packages are available with JD14 engines for easy, low-cost integration.

- The JD14 is compatible with renewable diesel fuel and biodiesel blends.