After 20 years in marketing, Stacy resigned from a position as a strategic marketing analyst and joined her husband, Greg, at the fledgling Equipment Experts, Inc. At that time, the company had 4 employees and was not profitable. Through many trials and tribulations, Stacy and Greg have cultivated an outstanding team of 28 staff members. They are also recognized by Drive as a Masters of Shop Management accredited shop. Much of their success comes from a passion for customer service, constant improvement and always doing the right thing . This E-book is an extension of that passion and the culmination of years of experience as a leader within the truck and heavy equipment repair and maintenance industry.

Information was also sourced through interviews with leading fleet managers and

owners. The interviews resulted in identifying key pain points within the process.

They also offered inspiring quotes and anecdotes, many of which are shared

within this e-book.

A Note

To The Fleet Manager

Are you a fleet manager or owner that oversees commercial motor vehicles such as vans, trucks, trailers and heavy-duty equipment including forklifts, excavators, etc. Then this Ebook is for you!

Managing a fleet is a complex process with several moving parts. The reality is that many fleet owners and managers are simply baffled about how to effectively take care of their fleet. The lack of a holistic guideline to managing your fleet has led to costly and even dangerous practices. A minor oversight can lead to a costly repair, vehicle downtimes and lapses in your business production.

Proper fleet management will reduce breakdowns and lengthen the lifespan of vehicles. Company owners and fleet managers should strive to maximize their vehicle investment by improving efficiency, productivity, and longevity. This e-book will provide a structure and process to optimize your fleet so that you can focus on your business and driving profitable results.

*This should serve as a guide and reflects the opinions of industry professionals. However, always use your best judgment. Every situation is unique and you are responsible for your fleet, its safety and compliance.

Prolong the life of your equipment. Keep your Fleet healthy, it’s WAY less expensive than fixing a major problem.

Compliance – Federally regulated – It’s the law. While writing these E-book local DOT officers stopped by our shop and were checking compliance for one of our customers.

Save money – Every dollar you pay for maintenance will save you big dollars down the road, so to speak.

Plan and track your finances, and budget in taking care of equipment. Be in control and less reactive!

Stress Factor – Reduce stress and company drama. Focus on what you do to increase your profitability rather than random breakdowns.

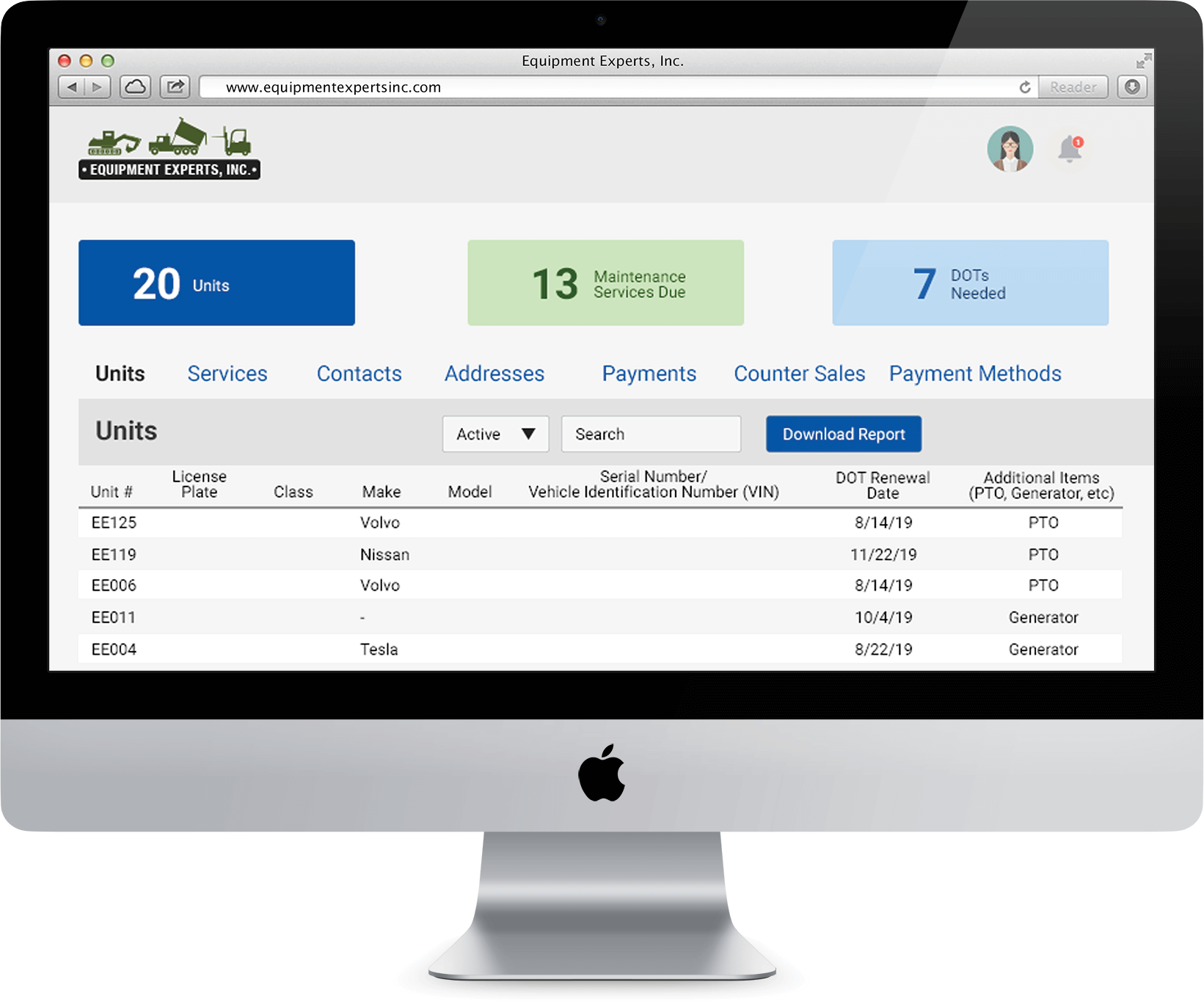

For proper fleet management, it is key to start with a source of information that has all of your fleet details in one place. Put your eyes on every piece of equipment that you are responsible for. If it’s not on your lot, call the repair shop, location, etc and have them send you a picture for verification. One fleet manager we knew simply thought one piece of equipment was very inexpensive to operate. Turns out that it wasn’t on the lot for several months. It was at a repair shop he didn’t know about. This leads to a constraint on his team because they didn’t have enough equipment to begin with, AND an unexpected/budget repair bill to get it back. Your fleet management verification process should contain all of the below specifications.

The next step in setting up your fleet management is to identify all of your fleet equipment by using intelligent numbers. This may only make sense to your organization, such as a rental inventory, delivery inventory, sales vehicles, earth moving equipment, etc. It just needs to make sense when you look at the number and you can clearly identify what type, kind, designated use of the equipment is. TRUST ME, numbering them 1, 2, 3 does not work. Even when you are just beginning and only have 1 piece of equipment, be hopeful, and someday it might be 10 or 20 pieces of rolling stock you are responsible for. It could happen to anyone!

Identify your method of data storage. This is the foundation of fleet management success. Below are several methods of keeping tracking of required maintenance.

Ease of use and view. Mostly used by in house mechanics or dispatchers in the shop.

Not shareable. Easy to lose/erase. Difficult to update.

Organization, Easy to Use, Use of formulas

You must be able to keep it updated. Hard to see. Easy to overlook.

Industry specific, Easy to organize, predefined data fields.

Company expense. Must get everyone to use it. Difficult to find the right software specifically for your company.

More transparent. Offers more visual information. It’s free, no extra data to enter, easy to manipulate.

None.

As a fleet manager, having an easy-to-follow fleet key control system in place is crucial. How many times have you spent hours searching for keys and they are in someone’s pocket at home.

2 keys for drivers. Store in a key control lock box that is for driver access only.

1 key for mechanics access only. Keep this key in a lock box for mechanics only.

1 key for Dispatch access. Kept in a separate key control box for dispatch only.

1 key for Manager. Keep in a lock box only a manager has access to.

An essential part of your fleet maintenance and repair is planning your strategy. Before launching into planning you should first understand your state and federal compliance. The laws should be taken heavily into consideration and will determine your DOT’s and preventative maintenance schedule. So first and foremost, keep updated on the laws. It’s is your responsibility!

*Always check with the Federal Department of Transportation for updated laws.

Once you understand the implications of compliance, you can then start to put together your fleet maintenance and repair budget. This prompts the question of how do you budget for your fleet? Below are several options to choose from. Pick one and move forward with it. Alway remember to prepare for the worst and hope for the best.

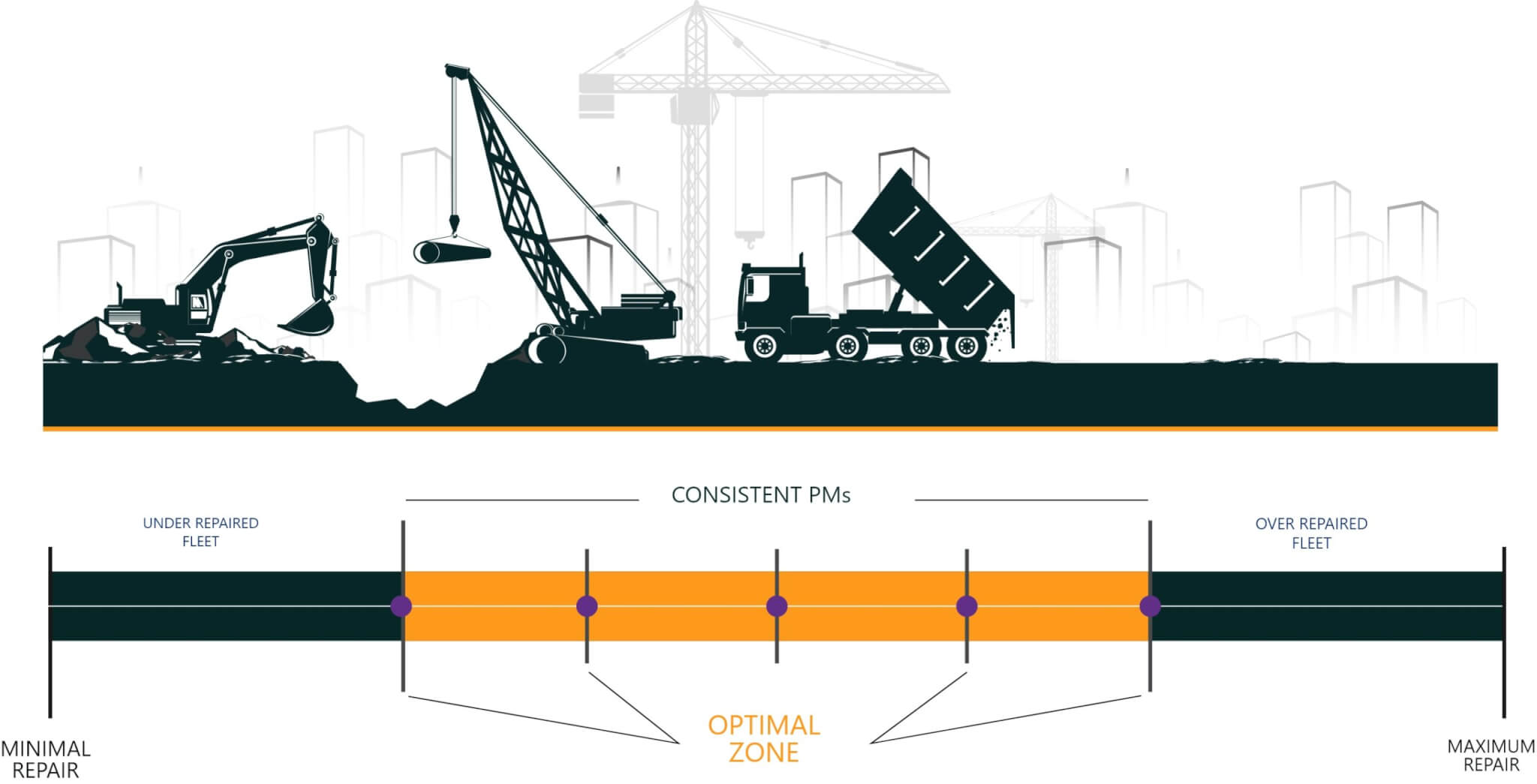

If investing your own funds seems out of reach, you can always work with a banker or an equipment line of credit. That way you are not reacting financially. Now it’s time to start planning your fleet maintenance and repair schedule Some companies organize their fleet maintenance and repair by having all of their DOTs and PMs done at one time. We suggest the following approach.

| Heavy Equipment & Forklifts | Every 200-250 hours |

| Trucks | In city driving (5,000 miles). Freeway driving (12,000 miles) |

Review your owner’s manual for any additional services that should be performed such as 2,000 hour service, etc.

* Note: Always check and follow your manufacturer’s owner guidelines. If your business is seasonal, be prepared to deliver for your typical heavy season, which may have a different schedule.

You need to set standards of measurement to understand if your efforts are working. Below are some crucial KPI’s (Key Performance Indicators) that should be consistently tracked and compared over specific timeframes.

Overall Cost = Maintenance + Breakdown Repairs + DOT’s + Towing

HIDDEN COSTS OF VEHICLE DOWNTIME |

|

| Drama Cost | This is what happens when you are down equipment that affects your ability to deliver. Also, who is taking the equipment to the shop, how long will it be there. We call this developed traffic. Work that is created for some reason that impedes your regular jobs. |

| Lost Opportunity | When focusing on a fleet, when you could focus on growth, customer service and delivery. |

Once you understand compliance, budgeting and have set KPIs, you are ready to take action and choose your fleet maintenance pro! There are several routes to take when it comes to the management of your fleet. Below are the main solutions for your fleet maintenance pro and the pros/cons of each.

They can be great but sometimes they might not have the level of experience needed to perform all the work needed. They can get overwhelmed if they don’t have the manpower or resources needed to execute. If breakdowns become their priority, they can ignore standard maintenance and endanger the health of the entire fleet. If you need one, more than likely you will need 2. One for maintenance and one for large jobs.

Expensive option and small customers can be unimportant. Urgency may not be their priority. The goal may be to sell you more equipment.

They can be great but can also just be learning how to run a business. Also, you have to check if their intentions are honorable? Do they care about their customers?

Can be your partner in planning. Can help educate your team. Can give advice on the status of your fleet. Can do service on site. Care about their customers big or small.

Once you get the ball rolling, you MUST setup fleet maintenance tracking to stay on top of key milestones. It is best to tackle critical actions in the below timeframes.

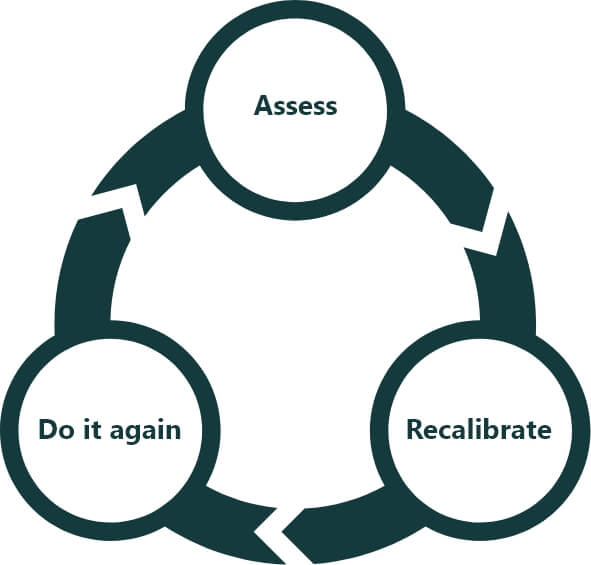

Through your fleet maintenance tracking, you will be able to find the area of most improvement and focus on that. When you get it right, make it a policy. Along the way there are going to be unique scenarios that arise. Below are some unique questions that you may encounter as you continue to improve your process.

Get inspections of each truck and have a sit-down and heart to heart with your service provider. Look at the costs to get each truck in the following conditions (fair, good, excellent). What will get you through to deliver, while you rebuild your assets? In this case, a trustworthy partner/business person will have some options for you. Sometimes new parts, reconditioned parts, and used parts (not usually recommended) can get you through a drastic period.

These professionals can give you indications where to spend money, and where to get rid of assets and get new ones.

Don’t forget pre-purchase inspections on used trucks or equipment, this can give you great information on whether to buy and/or bargain with.

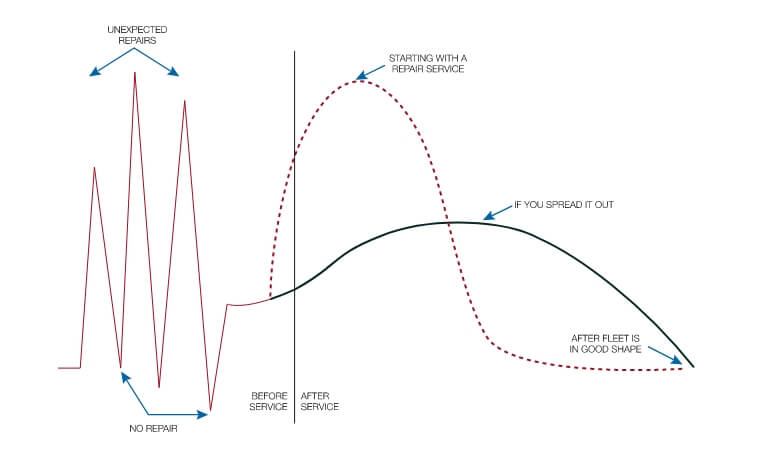

Below is a graphic which illustrates what will happen if you don’t get a maintenance program initiated.

It depends on what is right

for you business:

Your heavy equipment and truck fleet services are fueled by your knowledge. Best practices in the industry are constantly evolving. Compliance requirements are also changing. Make sure that you stay educated and up to date on the latest practices and regulations.

Equipment Experts is a company headquartered in Lakewood, Washington. The company’s mission is to be the best independent truck repair and maintenance company for forklifts, fleets, diesel trucks, and heavy equipment. The company seeks to remove the hassles of repairing and managing fleets of trucks and other diesel equipment so that customers can focus on their core businesses and improving their lives.

If you need any additional information about fleet management or require assistance managing your fleet, contact us at 253-365-6591 or visit